Question: What is the most cost-effective way of driving a 1,500 gallon-per-minute (gpm) ratable NFPA 1900 compliant fire pump in a new fire truck? Asked by: Jay Johnson, Chief Sales Officer, Rosenbauer America

Answered by: Wayne Hable, P.E. Chief Engineer, Darley

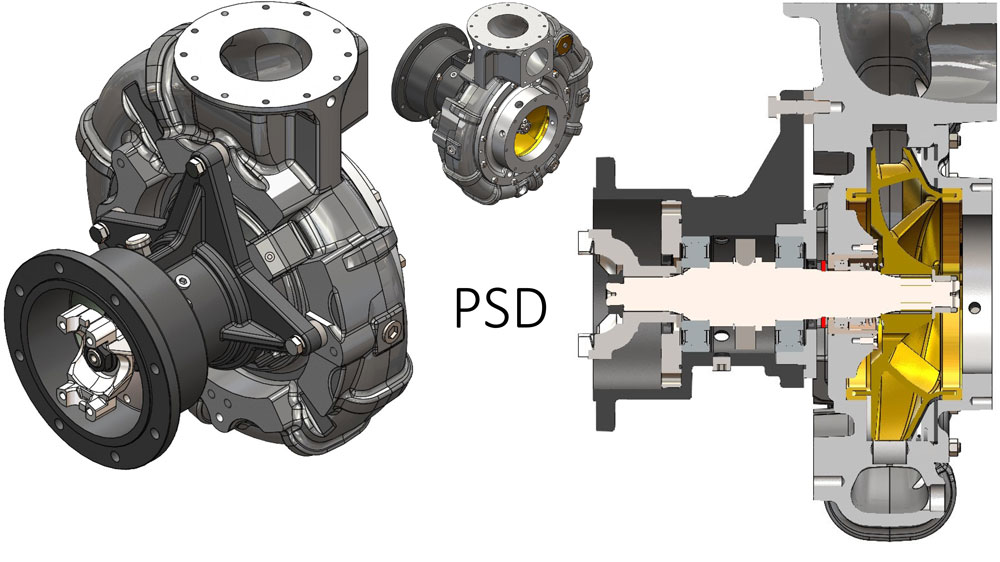

Look no further than Darley’s direct drive PSD 1500 fire pump that relies entirely on the Power Take Off (PTO) gearing for increasing the speed between the engine and pump impeller to attain all the necessary NFPA 1900 performance points with the engine governed speeds that exist today.

Most are unaware that PTO manufactures today no longer limit some of their PTO output speeds to 2,500 rpm anymore. With a newly allowed 4,000 rpm PTO output speed, Darley PSD 1500 fire pumps can easily attain a 750 gpm at 250 psi performance point with plenty of safety margin left on the engine’s governed speed.

With at least a 334 lb-ft continuous PTO output torque rating, a Darley PSD 1500 fire pump can easily attain a 1500 gpm at 165 psi overload performance point without exceeding this torque rating.

Many are unaware that Allison Transmission makes a 3000 EVS transmission model that has Top/Side PTO openings that can easily power these pump performance points. Not to knock split-shaft midship pumps, which Darley sells many of, but a direct drive pump is significantly less expensive than midship fire pumps simply because a direct drive fire pump doesn’t have a gearbox, nor does it have a split-shaft transmission. The PTO is lubricated by the Allison Transmission’s lubrication system which has an oil filter and can have a cooler. The PTO is engaged/disengaged by the Allison Transmission hydraulic pump so all the necessary complexities of a midship transmission are minimized with a PTO drive train.

A PTO is shifted by a push button control in the cab or pump panel. A PTO can be “hot” shifted which implies the PTO can be shifted while the engine and driveline is spinning which we all know is a no-no with a midship pump. A PTO drivetrain allows for pump and roll capabilities as well as engaging the pump without anyone having to leave the safety of the cab – think of this feature the next time you respond to a roadside car fire. If you use an Allison 3000 EVS transmission with Top/Side PTO openings as well as a Chelsea 871XJFJP-*5 PTO (334 lb-ft continuous torque rating & 200% speed ratio) or a Muncie CS41-A1012 PTO (343 lb-ft continuous torque rating % 200% speed ratio) your Darley PSD1500 pump performances points would be as indicated in the below chart.

Direct drive pump capable of: 1,000 gpm and

1,250 gpm NFPA ratings thru 1-6″ 1,500 gpm,

1,750 gpm and 2,000 gpm NFPA ratings thru 2-6″.